Experiencing a slower speed on your computer shows that there is a slight change. And it could be as a result of dirt or corrosion on the circuit board of that computer. So, finding out how to clean a circuit board is certainly a step in the right direction.

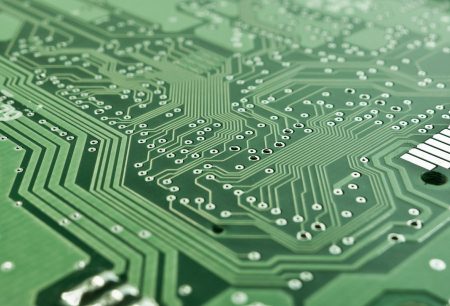

A circuit board is a piece of technology that ensures the assembly of electrical or data circuits on a horizontal piece of material.

These plastic boards and their components provide the basic technology from phones to computers, television, and other communication or electronic devices.

The circuit board is important as it helps connect the electronics of a device in a compact space. With a circuit board, all the components of a device are connected to a power source while being insulated.

Table of Contents

What Are The Components Of A Circuit Board?

The following are components of the circuit board:

1. Battery.

2. Capacitor.

3. Diode.

4. Inductor.

5. Integrated circuit (IC) .

6. LED (light emitting diode).

7. Resistor.

8. Switch.

9. Transistor.

A circuit board is made up of different components that are vital in its functioning.

- Battery: Provides power for a circuit,

- Capacitor: This is a component that can quickly hold or release an electrical charge

- Diode: A diode controls electricity on a circuit board by making it to move in one direction

- Inductor: An inductor stores energy from a current as magnetic energy

- IC (Integrated Circuit): A chip that may contain many circuits and components in miniaturized form and that typically performs a specific function

- LED (Light Emitting Diode): This is a small light on a circuit board that is used to provide visual feedback

- Resistor: A resistor regulates the flow of current by providing resistance

- Switch: A switch either block current or allows it to flow, and this depends on whether it is closed or open

- Transistor: A type of switch controlled by electrical signals

How to Clean A Circuit Board

There are different ways to clean a circuit board and this depends on the severity of the condition.

Compressed air is used to remove dust and dirt on the circuit board. While spot cleaning is the best fit for corrosion. Baking soda is used for severe corrosion.

Compressed Air

How do you use compressed air to clean a circuit board?

Follow these steps to clean a circuit board using compressed air:

1. Shut down your computer system or device.

2. Spray compressed air into the central processing unit at short spells.

3. Open up the central processing unit (CPU) using a screwdriver. This ensures entry and access to the computer circuit board.

4. Spray the circuit boards at short bursts while ensuring the nozzle of the canister is placed not too close to the circuit board.

Cleaning a computer system while it is still on can damage the computer and it could also lead to electrocution. The compressed air is in a canister that has a nozzle for spraying. The nozzle of the compressed air canister is inserted into the fan exhaust ports.

Ensure the canister is upright and not turned upside down as it could have a negative effect on your component. Also, spraying the computer for a long time can freeze the components of your computer.

How do you spot clean a circuit board?

The following are steps to take to spot clean a circuit board:

1. Gently brush off grime and dirt on the circuit board.

2. Use baking soda to clean the circuit board.

3. Wet a cotton swab with at least 90% isopropyl alcohol and wipe the board clean.

4. Use compressed air in a canister to blow away dislodged grime when the alcohol has dried.

Spot cleaning helps to remove grime that would have lodged in the circuit. Grime can build up near circuit generators and at the top of the pathway of the circuit.

Ensure that the cotton is not too wet so that there would not be so much moisture that could damage the circuit board. So, squeeze the cotton swab ensuring it is only slightly damp.

Do not use force when using a cotton swab. Make sure the canister is upright with the nozzle not to close to the circuit board. Remember to spray in short bursts to avoid freezing the computer components.

How to Remove Corrosion From A Circuit Board

Follow these steps to remove corrosion from a circuit board:

1. Disassemble the device to get access to the circuit board.

2. Mix 1 or 2 tablespoons of distilled water and 1/4 cup of baking soda to make a thick paste.

3. Apply the baking soda paste on the corroded area of the circuit board and leave it for 20-30 minutes to dry.

4. Use a soft bristled brush to scrub the corroded area.

5. Wash the circuit board with water when the solution has dried.

6. Spray the circuit board with a household cleaner and allow it to sit for about 15 seconds.

7. Use a soft brush to scrub any leftover corrosion.

8. Use a microfiber cloth or lint-free towel to clean debris or moisture.

9. Set your oven to a temperature of 170 degrees Farenheit. When the oven gets to this temperature, turn it off.

10. Place the circuit board inside the oven for about 3 hours to completely remove moisture.

You can also use the eraser of a pencil to remove significant corrosion. The pencil eraser is used to lightly rub off the corrosion.

This is a good stopgap measure especially if you want to avoid using baking soda. Because if baking soda is not used properly, it can damage the circuit board.

The pencil eraser is good for cleaning circuit boards with copper components.

Corrosion is usually caused by a spoilt battery that leaks acid near the circuit board. So, ensure you remove the bad battery and replace it.

Finding the spoilt battery is easy as it is also corroded. Make sure that you are wearing rubber gloves when you take out the battery.

Remove the battery and dispose of properly. Then, clean the battery slot and replace it with a new battery.

Check out these interesting articles from our previous post:

- How to Clean Up Blood

- How to Clean Mold Out Of A Fridge

- How Often To Clean A Dryer Vent

- How to Clean An AC unit

- How to Clean Dog Pee From A Couch

- How Long Does It Take To Clean A House

Conclusion

In order to keep your circuit board in good condition, ensure that all electronic devices are switched off when not in use. Also, keep the circuit board away from water.

It is necessary to have a basic knowledge of these devices, especially when opening them up to clean the circuit boards. This is necessary so that these devices can be closed back up without hassle.

How to Clean A Circuit Board – Related FAQs

Can You Fix Water Damaged Circuit Board?

Water damaged circuit boards can be fixed. However, this is determined by the degree of damage. When a circuit board is exposed to water, the damage occurs within seconds. The longer it stays, the worse it will get.

There are several factors that determine if the circuit board can be repaired or not. They include: time the circuit board was exposed; the type of damage; the time the circuit board stayed before a repair is considered; and the cost of repair.

Before you clean water damaged circuit boards, remove the battery, power supplies, and power connectors. This will protect you from harm and any short-circuiting of your device. You must be careful not to expose other connectors that are already corroded.

Can You Use Acetone To Clean A Circuit Board?

The use of Acetone for circuit board cleaning is neither safe nor recommended. Acetone is a very strong chemical. As a result, it can dissolve the plastic of the Printed Circuit Board (PCB).

Specifically, Acetone can damage the soldier masks and silkscreens on a circuit board. These components protect the circuit boards against electrical shorts and corrosion. This can lead to total damage of the circuit boards or reduction of its lifespan.

Acetone can also dissolve ABS plastics, another type of plastic found on a circuit board.

What Causes Circuit Boards To Fail?

Circuit boards failure can be caused by:

- Failure of the component design: This can result in overheating, power failure, and incorrect placement of the components. Other related issues are fluid leakage, burned components, soldiering issues, bad components, and component barrier breakage.

- Poor quality of components: This can result in poorly soldered cold joints, insufficient thickness of the circuit board, counterfeit components, closely placed pathways and traces, and poor connectivity in between circuit boards. Other related issues are breaking, bending, and material defects.

- Age

- Environmental factors: Issues related to environmental factors are accidental impact caused by falls, thermal stress, dust, heat, moisture, power surges or overloads, and electrostatic discharge at the stage of assembly.

What Is The Difference Between 70% And 99% Isopropyl Alcohol?

The differences between 70% and 99% Isopropyl alcohol (IPA) are:

- 70% IPA is used as a disinfectant against fungi, viruses, and bacteria while 99% IPA is used as a cleaning agent or solvent for industries that manufacture products that are water-sensitive.

- 70% IPA does not evaporate fast while 99% IPA evaporates instantly.

- 70% IPA contains some percentage of water for effectiveness while 99% IPA does not contain water.

- 70% IPA has a longer shelf life since it takes time to evaporate while IPA has a short shelf life.

- 70% IPA denatures protein and is used in breaching cell walls while 99% IPA coagulates protein and is used to clean circuit boards and other electronics.

- 70% IPA is cheaper than 99% IPA.

How Do You Dry A Circuit Board?

To dry a circuit board, do the following:

- Remove the circuit board from its case, if possible. Also, remove the battery from the circuit board.

- Use a hair dryer to dry the circuit board.

- Rinse the circuit board with clean water if it was exposed to salty water. Then dry the circuit board.

- Insert a new battery and download the data after drying.

Note that you must allow the circuit board to dry thoroughly before you insert a battery and start using it. Failure to do this may damage the circuit board entirely.

How Do You Know If Your Circuit Board Is Damaged?

Follow these steps to check if your circuit board is damaged:

- Remove the equipment cover.

- Inspect the circuit boards and ensure that they are plugged in tightly.

- Inspect each plug-in component for any signs of dirt or corrosion.

- Look for foreign objects or water around the circuit board.

- Inspect secondary wiring plugs for signs of corrosion or wear.

- Look for melted, discolored, blackened, swollen, or broken components of printed circuit traces.

- Look for components with broken leads or wires.

- Inspect the circuit board for any crack.

If you notice any of the above signs on your circuit board, repair them, or change the parts altogether.

How Do You Know There Is A Short In A Circuit Board?

To fix a short in a circuit board, do the following:

- Push the ‘Power’ button to turn the digital multimeter on.

- Switch on the measurement setting on the DC current multimeter.

- Test all red and black probes of the multimeter on the circuit board. A short is indicated when there is a zero current reading.

- Test all the wires that connect all devices on the circuit board.

Note that the multimeter is designated by ‘A’ (Amp) with straight lines all over it.

How Do You Clean A Circuit Board That Is Wet?

To clean a circuit board that is wet, do the following:

- Disassemble the device.

- Submerge the circuit board with distilled water or isopropyl alcohol in a container.

- Remove the circuit board after a short time.

- Use a soft brush to remove grime on the circuit board. Allow it to dry.

Preferably, use a desk lamp or blow dryer on the lowest setting to remove moisture from the circuit board. Check the battery before assembling your device. If it is faulty or damaged, kindly replace it.

What Tools Can Be Used To Clean A Printed Circuit Board?

The following tools can be used to clean a printed circuit board:

- Paintbrush or soft-bristled brush. These brushes can get into small gaps or spaces on the board. Make sure the brushes are not hard, otherwise, they will scratch the circuit board.

- Microfiber cloth or Lint-free towel. They are very effective tools for cleaning circuit boards as they wipe off cleaning solutions quickly. However, ensure they are lint-free so that you don’t leave debris on the device in the process of cleaning.

- Desk lamp, blow dryer, or oven. They help to remove the remaining liquid or moisture from the circuit quickly, after cleaning. This prevents damage to the circuit board.

What Conditions Are Circuit Boards Exposed To?

The following are conditions circuit boards are exposed to:

- Water spillage. If water splashes or spills on circuit boards, they are easy to repair. But care must be taken to clean them properly so that they don’t corrode the circuit board.

- Humidity or moisture. Moisture is not a suitable condition for circuit boards. When it combines with dust, it creates a sludge coating that can result in corrosion or overheating.

- Submerging in water. Submerged circuit boards can damage the board with an eventual corrosion. This can also occur even if the device was switched off when it was submerged in water.